Research

Introduction

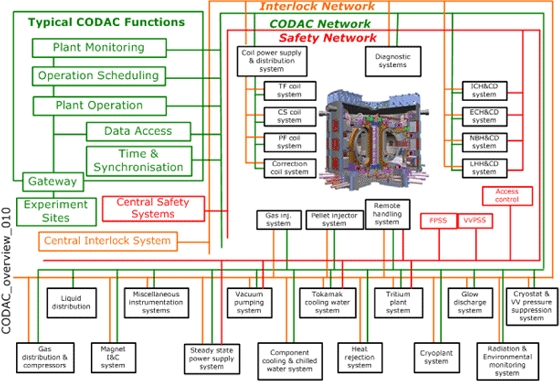

The ITER device is composed of many technical subsystems that are to be procured in-kind from the 7 participating countries. These technical subsystems are in themselves individually large and complex, generating large volumes of technical and experimental data. The functionalities of subsystems should be combined in a coherent and synchronized fashion to ensure the integrated plant operation.

The role of CODAC (COntrol, Data Access and Communication) is to ensure continuous, optimal and reliable coordination of all these technical systems, configuring them, synchronizing their functions and retrieving their data, for the integrated operation of all the ITER project equipment. Providing the infrastructure for optimal operation of the burning plasma in complex feedback loops is also an essential component of CODAC. Technical subsystems will be maintained by the ITER project after final acceptance. To reduce the number of technologies and methodologies to be guaranteed by ITER, the procured subsystems are subject to a set of standards and methods. Each procurement Instrumentation and Control (I&C) implementation must comply with these imposed standards.

Objectives

The major objective of the CODAC system is to provide the infrastructure to ensure the continuous, reliable, integrated operation of the ITER plant (with and without plasma). To accomplish its objective, CODAC provides the functionalities as follows:

- Coordination and configuration of ITER operation

- Synchronization of the ITER subsystems

- Plant operation and retrieval of experimental data

- Provision of infrastructure for plasma control

-

Integrated operation of ITER plant:

- Continuous monitoring of the plant status

- Display of the plant system status

- Preparation/Automation of ITER operation

- Data archival/storage/provision

Necessity of the development

ITER CODAC can be compared to the nerve system of life. The whole ITER plant is completed as an "integrated plant" by the software integration using CODAC, as well as the hardware integration. Thus, securing the CODAC technology has a great importance in the course of Korean power plant development program, constituting the rationale of choosing CODAC as one of the ITER core technology. Another benefit to be followed is that CODAC can open up more opportunities for Korean industries to participate in the ITER construction project.

Operation of a Tokamak Reactor

Current status of the development

ITER CODAC is categorized into 7 subgroups according to their functionalities:

- Supervision Group

- Data Handling Group

- Monitoring Group

- Automation Group

- Common Service Group

- Network Group

- Enabling Systems Group

Each subgroup is also divided into two to several subsystems, resulting in 43 total subsystems, to facilitate the development and division into future CODAC procurement packages. At the present time (March, 2009), many technical contents of the subsystem conceptual design are in To Be Determinted (TBD) state, most of which will have to be completed during the Preliminary Engineering Design phase.

ITER-KO have proposed the following major research themes for CODAC development, based on the analysis of ITER conceptual design:

- ITER middleware design using EPICS

- Optimization of plant operation: development and implementation of optimization algorithm

- Exploitation of KSTAR control system as the prototype for ITER CODAC

- Capabilities for Long pulse operation: Optimization of hardware/software architecture for real time plasma control. Development of optimized pulse rescheduling system

- Optimization of data access: Development and implementation of algorithm

- Remote participation system

At present, Korea Institute of Fusion Energy (KFE) is conducting an IO-funded Task Agreement on "Investing and demonstrating the use of EPICS for tokamak control", which will provide the technical basis for adopting EPICS for ITER CODAC design and implementation.

Expectation

CODAC involves up-to-date technologies such as information and communication, plant automation, real-time control. So, the technologies acquired during the execution of the CODAC project can be transferred to Korean high-tech industries.

보안문자를 입력 후 확인 버튼을 누르세요.